Runtime MDT: Monitoring Operational Use for HVAC and Utility Equipment

Runtime MDT monitors the operational "on" time of equipment like HVAC units, pumps and fans, providing valuable insights that support timely maintenance and enhance overall system performance.

Runtime MDT Overview

Runtime MDT tracks the on/off states of equipment such as HVAC units, pumps, and fans, capturing how long devices are running to enable proactive maintenance. This functionality ensures reliability and optimal performance across various utility systems, reducing downtime and improving efficiency.

The device is designed for easy integration with existing systems, allowing property managers to swiftly implement monitoring without extensive modifications. By providing clear visibility into equipment operation, Runtime MDT supports effective resource management and operational planning.

By integrating this device into their utility monitoring solutions, users can achieve operational efficiency and realize cost savings through reduced errors and streamlined processes.

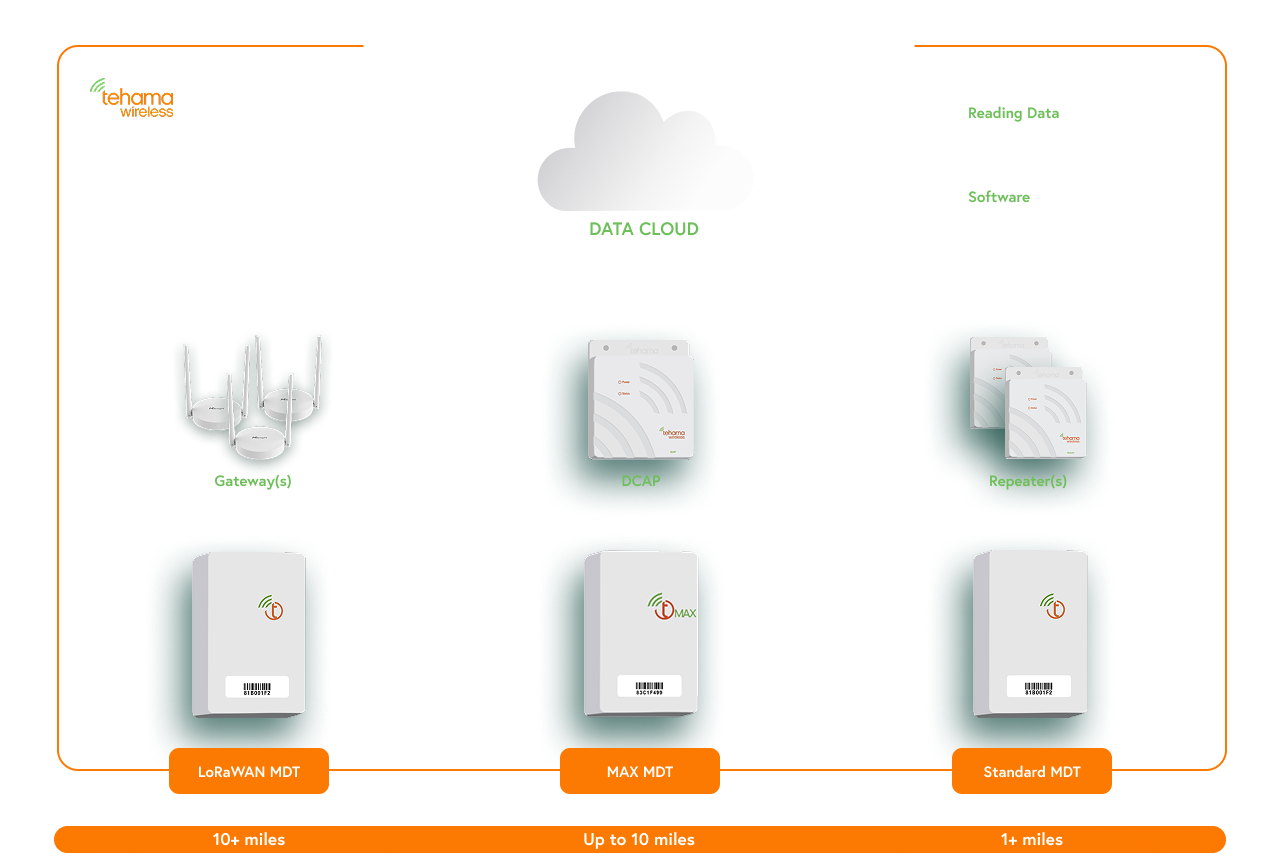

Supports wireless ranges from 1 to over 10 miles, with extended coverage via repeaters (Standard and MAX) or additional gateways (LoRaWAN) for flexible deployment across diverse property layouts.

Benefits

Runtime MDT enhances utility monitoring by providing precise measurements and efficient data transmission for effective management.

- Records "on" time in seconds for accurate billing.

- Transmits running count via radio to DCAP for automated data retrieval.

- Detects zone valve control state or relay switch inputs for versatile applications.

- Offers an optional internal temperature sensor or external thermistor for accurate readings.

- Provides a 5-7 year battery life or an optional line-powered version for continuous operation.

- Features a Time of Use option with memory and 15-minute interval data backup.

Whether you need to enhance billing precision or streamline utility management processes, Runtime MDT provides reliable and efficient solutions.

Applications

Multifamily

Housing

Runtime MDT records the "On" time in seconds of various distributed energy measurements, providing accurate utility usage tracking for multifamily housing applications.

Commercial

Properties

Runtime MDT optimizes utility management in commercial properties by allowing the monitoring of 24VAC thermostat control states or dry contact inputs effectively.

Manufactured

Homes

For manufactured home communities, the Runtime MDT simplifies utility tracking and monitoring, ensuring that property managers can accurately assess energy usage and billing.

ESG &

Sustainability

By leveraging advanced data tracking, Runtime MDT supports sustainability initiatives, helping property owners optimize energy usage and reduce environmental impact.

Documentation & Resources

| Input Type | Compatible with reed switch and piezoelectric pulse generator meters. |

| Communication Range | Up to 3500 ft (Standard), nearly 10 miles (MAX/LoRaWAN). |

| Battery Life | Operates on two field-replaceable AA lithium batteries with a typical life of 5-8 years. |

| Operating Temperature | Ranges from -20°F to 145°F. |

| Input Options | Available with single or dual pulse inputs for co-located setups. |

| Waterproof or Water-Resistant Options | Available in the Submersible model, a pulse or encoder unit, with non-field replaceable C battery, designed for use in environments where complete water exposure is expected. |

Tracks and reports equipment runtime by detecting relay or thermostat signals. Optional external power.

Instructions for configuring and sending custom daily reports from MDTs using email or FTP delivery.

Wiring instructions for connecting the MDT to compatible meters.

Comprehensive steps for configuring and integrating MDTs with the DCAP system

Template for importing site configuration data to Tehama Wireless.

Instructions for replacing batteries in field-deployed MDT units.

Tehama Wireless provides a five-year warranty for its products.

-

Case Study | Guardian Water & Power

Case Study | Guardian Water & PowerGuardian Water & Power encountered significant challenges in outdoor submetering due to harsh weather conditions. Frequent disruptions led to costly repairs and inconsistent data collection, adversely affecting service delivery and customer trust. Recognizing the urgent need for a reliable solution, they sought innovative technology to enhance their operations.

Challenge

- System downtime due to harsh weather

- Repairs were difficult and costly

- Cellular technology meant inconsistent data collection

-

Case Study | Kimco Realty

Case Study | Kimco RealtyKimco Realty Corporation faced considerable challenges in billing their 7,000 tenants accurately for water usage across a diverse portfolio of retail properties. A lack of standardized methods for dividing costs led to disputes and frustration, resulting in millions in uncollected revenue. Recognizing this issue, Kimco sought innovative submetering technology to streamline billing processes and enhance tenant satisfaction.

Challenge

- Inconsistent tenant water billing methods

- Tenant disputes over water costs

- Millions lost in uncollected revenue

-

Case Study | Fair Energy Submetering

Case Study | Fair Energy SubmeteringFair Energy Submetering faced challenges tracking utility usage and identifying issues such as leaks across various properties. In search of more detailed data for effective management, they turned to Tehama Wireless’ advanced submetering sensors. This innovative technology enabled swift identification of problems, allowing them to avert potential disasters.

Challenge

- Inaccurate tracking of utility usage

- Difficulty identifying leaks in properties

- Limited data hindered effective management

Videos

-

Introduction to the Web App

-

DCAP Troubleshooting

-

Web App Troubleshooting

-

DCAP-TFA Installation

-

Get Started with the Web App

-

Monitoring and Maintaining a System

-

Commissioning a Meter Display Using the Mobile App

-

Requesting and Approving Grants with the Web App

-

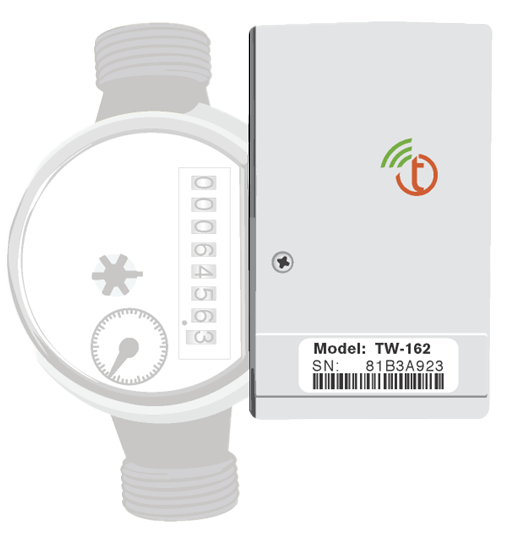

Wiring a Water Meter to an MDT

-

The CIT in Detail

-

Commissioning a Site

-

Hardware Setup

-

System Overview

-

Getting started with the CIT

-

Connect Mobile App Overview

-

DCAP Configuration

-

Commissioning MDTs and Repeaters

-

Setup CIT Alerts and Reports

-

Monitoring Data and Network Health

-

Configuring the Display on an MDT

-

Wiring the MDT to its Associated Meter

-

Introduction to the CIT

-

How to Find the IP Address of a DCAP

-

ModBus P2P Reads in the CIT and Web App

How It Works

Gateway or DCAP captures data from connected submeters and relays it to central management systems, ensuring accurate data collection and near real-time monitoring for improved utility management.

This diagram illustrates how Tehama Wireless devices work together to optimize metering solutions

Related Products

-

Pulse MDTTracks pulse output meter usage for accurate billing

Pulse MDTTracks pulse output meter usage for accurate billing -

Smart+ MDTEnables near real-time data and advanced alerts with SunSonic® meters

Smart+ MDTEnables near real-time data and advanced alerts with SunSonic® meters -

Encoder MDTTracks encoded output meter usage for accurate billing.

Encoder MDTTracks encoded output meter usage for accurate billing. -

Outsider MDTDirect physical MDT connection on Norgas Versamag water meters.

Outsider MDTDirect physical MDT connection on Norgas Versamag water meters. -

Leak Detection MDTQuickly detects leaks to minimize water events and reduce costly damage.

Leak Detection MDTQuickly detects leaks to minimize water events and reduce costly damage. -

Modbus MDTIntegrates with ModBus P2P-compatible systems for enhanced data.

Modbus MDTIntegrates with ModBus P2P-compatible systems for enhanced data. -

DCAPAggregates and processes submetering data for efficient reporting.

DCAPAggregates and processes submetering data for efficient reporting. -

DCAP-TFAStandard DCAP functionality plus receives Inovonics PMT and repeater transmissions.

DCAP-TFAStandard DCAP functionality plus receives Inovonics PMT and repeater transmissions. -

Solar DCAPProvides a complete solution for extending communication range in remote locations.

Solar DCAPProvides a complete solution for extending communication range in remote locations.

FAQs

Runtime MDT connects with 24VAC thermostat control signals or relay switch inputs and can also be paired with an optional internal temperature sensor or external thermistor for location-specific readings.

Runtime MDT records "on" time in seconds for various distributed energy measurements and routinely sends this data to the DCAP or Gateway for processing.

By accurately monitoring energy usage via runtime measurements, it helps identify usage patterns and inefficiencies, enabling informed decisions for energy savings.

Runtime MDT supports wireless communication ranges from 1 to over 10 miles, with extended coverage enabled through repeaters (Standard and MAX) or additional gateways (LoRaWAN), depending on the configuration and environment.

Runtime MDT transmits data via radio to the DCAP or Gateway once an hour, recording "on" time of the measured outputs.

Runtime MDT is powered by two AA batteries and has a typical battery life of 5 to 7 years under normal conditions.

Yes, Runtime MDT is designed for easy installation, connecting directly at the thermostat or zone valve.

Yes, the collected data from Runtime MDT can be transmitted to the DCAP or Gateway and incorporated into existing utility management software.

Runtime MDT is available in multiple configurations, including options for a 24VAC input or dry contact input, with additional features like temperature sensors.

Runtime MDT is designed to operate in indoor environments ranging from -20°F to 145°F and is rated for up to 90% relative humidity, non-condensing.

Routine checks on battery status and functionality are recommended, though specific maintenance requirements are minimal.

Yes, Runtime MDT can detect connection integrity issues and send alerts if a connection has been tampered with or interrupted.

Related Blogs

Underwriting Readiness Is Increasingly Tied to Proof, Not Promises

For billing partners, underwriting pressure doesn’t arrive as a theoretical risk discussion. It…

Tehama MAX Range for Simplified Long-Distance Submetering

As property managers and business owners strive for enhanced efficiency in utility management, the…

Tehama Standard Range for Affordable Extended-Range Submetering

As property managers and business owners strive for cost-effective utility management, the choice…